If you’ve been searching for ways to elevate your sublimation printing projects, you’ve likely come across sublimation spray as a game-changing solution. This innovative product has revolutionized how crafters, small business owners, and professional printers work with non-polyester materials. In this comprehensive guide, we’ll dive deep into everything you need to know about sublimation spray, from how it works to real-world applications that can boost your business.

What is Sublimation Spray and How Does it Work?

Sublimation spray is a specially formulated coating that allows you to apply sublimation ink to materials that wouldn’t normally accept it. Think of it as a bridge between your sublimation printer and surfaces like cotton, wood, leather, and other natural fibers. The spray contains polymer compounds that bond with sublimation ink during the heat press process, creating vibrant, permanent designs on previously incompatible materials.

The science behind sublimation spray is fascinating. When you apply heat and pressure to sublimation ink, it transforms from a solid directly into a gas without becoming liquid first. This gas then bonds with polyester fibers at the molecular level. Since natural materials don’t have the right chemical structure for this bonding, sublimation spray creates an artificial polyester-like coating that accepts the sublimation dye. The result? Professional-quality prints on cotton t-shirts, canvas bags, wooden signs, and countless other items.

According to industry research from Sublimation 101, the global sublimation printing market is expected to reach $9.5 billion by 2027, with spray solutions playing an increasingly important role in this growth. This expansion is driven by crafters and entrepreneurs who want to offer more diverse product lines without investing in multiple printing technologies.

Types of Sublimation Spray Products Available

The market offers several varieties of sublimation spray, each designed for specific applications and materials. Understanding these differences will help you choose the right product for your projects and avoid costly mistakes that could waste materials and time.

Water-Based Sublimation Sprays

Water-based formulas are the most popular choice among beginners and home crafters. These sprays have low odor, clean up easily with water, and are generally more environmentally friendly than solvent-based alternatives. They work exceptionally well on cotton fabrics, canvas, and porous surfaces. Most water-based sublimation sprays require 2-3 light coats for optimal results, with drying time between coats ranging from 10-30 minutes depending on humidity levels.

Key benefits of water-based sublimation spray:

- Non-toxic and low VOC emissions

- Easy cleanup with soap and water

- Suitable for indoor use without ventilation concerns

- Cost-effective for small to medium projects

- Compatible with most fabric types

Solvent-Based Sublimation Coatings

Solvent-based sublimation spray products deliver more durable results and faster drying times. Professional print shops often prefer these formulations for high-volume production because they create stronger bonds with substrates and resist fading better over multiple wash cycles. However, they require proper ventilation and protective equipment during application, making them less suitable for home studios without dedicated workspace.

The durability factor is significant. Testing conducted by printing equipment manufacturers shows that solvent-based coatings maintain color vibrancy for 50+ washes compared to 30-40 washes for water-based alternatives. This makes them ideal for commercial apparel production where longevity is a selling point.

Specialty Sublimation Sprays for Hard Surfaces

Some manufacturers produce sublimation spray specifically formulated for rigid materials like wood, metal, ceramic, and glass. These products contain different polymer ratios that adhere better to non-porous surfaces and withstand environmental exposure. If you’re creating outdoor signage, personalized cutting boards, or decorative tiles, specialty hard surface sprays will give you superior results compared to fabric-focused formulations.

Step-by-Step Application Process for Perfect Results

Applying sublimation spray correctly separates amateur-looking results from professional-quality prints. The application process requires attention to detail and proper technique, but once you master it, you’ll achieve consistent, stunning results every time.

Surface Preparation is Critical

Before applying any sublimation spray, thoroughly clean your substrate to remove oils, dirt, dust, and moisture. For fabrics, pre-wash without fabric softener and allow to completely dry. For hard surfaces, wipe down with isopropyl alcohol and let evaporate completely. Any contamination will create barriers that prevent proper adhesion and result in blotchy, uneven prints.

Temperature and humidity also play crucial roles. Ideal application conditions are 65-75°F with relative humidity below 60%. Higher humidity extends drying times and can cause the spray to bead up rather than form an even coating. Many professional printers use dehumidifiers in their workspace to maintain consistent conditions year-round.

The Application Technique

Hold your sublimation spray can or spray bottle 6-8 inches from the surface and apply in smooth, even strokes. Multiple thin coats always outperform one thick coat. Heavy application causes drips, uneven coverage, and wasted product. For fabric items, spray in a well-ventilated area or outdoors, using a spray box to contain overspray and protect surrounding surfaces.

Pro application tips:

- Shake the can thoroughly for 2 minutes before use

- Start spraying off the edge and sweep across the surface

- Overlap each pass by 50% for complete coverage

- Allow proper drying time between coats (check manufacturer specifications)

- Apply 2-4 light coats depending on material porosity

- Test spray pattern on scrap material first

After the final coat, allow the sublimation spray to cure completely before printing. Rushing this step causes the coating to transfer to your heat press rather than bonding with your design. Most products require 24 hours for full cure, though some fast-dry formulations are ready in 4-6 hours.

Materials You Can Transform with Sublimation Spray

The versatility of sublimation spray opens up an incredible range of products you can create. This expanded material compatibility is why many print-on-demand businesses are adding spray sublimation to their service offerings. Let’s explore the most popular and profitable applications.

Cotton and Natural Fiber Fabrics

Cotton t-shirts represent the holy grail for many sublimation printers. While traditional sublimation only works on polyester, sublimation spray lets you print full-color designs on 100% cotton with the same soft hand feel customers love. The process works equally well on cotton blends, linen, rayon, and bamboo fabrics. This capability dramatically expands your potential product catalog without requiring different printing equipment.

Market data shows that 68% of consumers prefer cotton over polyester for everyday clothing due to breathability and comfort. By using sublimation spray, you can serve this market segment while maintaining the production efficiency of sublimation printing. The key is proper coating technique and heat press settings adjusted for natural fibers.

Wood Products and Home Décor

Wooden items treated with sublimation spray have become incredibly popular in the home décor and personalized gift markets. Think custom cutting boards, family name signs, photo panels, and decorative boxes. The spray allows vibrant photo-quality images to bond with wood grain, creating a unique rustic-modern aesthetic that customers can’t get with other printing methods.

Basswood, birch, and maple work particularly well because of their light color and fine grain. Darker woods like walnut require lighter-colored sublimation spray primers to ensure designs show up properly. Many crafters create stunning contrast effects by leaving portions of the wood uncoated, allowing natural grain to show through around the printed design.

Leather and Synthetic Leather

The leather goods market represents a high-profit opportunity for sublimation spray users. Personalized leather wallets, bags, journals, and accessories command premium prices. Real leather requires specific spray formulations designed for its unique surface properties, but the results are worth the investment. Synthetic leather (often called vegan leather or PU leather) generally works with standard fabric sprays.

One successful Etsy seller reported increasing her average order value by 45% after adding custom leather products to her sublimation offerings using specialized sublimation spray. The key is sourcing quality leather that’s been properly tanned and prepared for coating applications.

Canvas and Tote Bags

Canvas bags sprayed with sublimation spray produce vibrant, gallery-quality prints that survive countless uses and washes. This makes them perfect for promotional products, retail merchandise, and personalized gifts. The heavy texture of canvas holds the spray coating exceptionally well, often requiring fewer coats than thinner fabrics while delivering more durable results.

Commercial applications include corporate event giveaways, wedding favor bags, farmers market shopping totes, and branded merchandise for businesses. The combination of eco-friendly canvas material and chemical-free sublimation printing appeals to environmentally conscious consumers willing to pay premium prices.

Choosing the Best Sublimation Spray for Your Projects

Not all sublimation spray products deliver equal results. The market includes various brands with different formulations, price points, and performance characteristics. Making an informed choice saves money and prevents frustrating failed prints that waste expensive materials and time.

Top-Rated Sublimation Spray Brands

Several manufacturers have established themselves as leaders in the sublimation spray category. SubliGlaze offers a water-based formula popular with craft businesses for its consistent results on cotton. Sawgrass, known for sublimation ink systems, produces complementary spray products optimized for their printers. A-Sub and Grafix also manufacture well-regarded options at various price points.

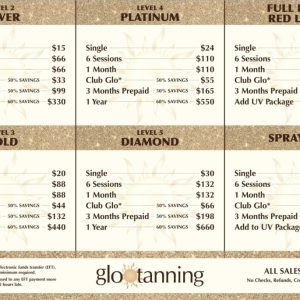

Price ranges typically fall between $15-35 per bottle, with coverage rates of 8-12 square feet depending on application thickness. While cheaper options exist, they often require more coats or produce inferior color vibrancy. Many experienced printers find that mid-range products offer the best balance of cost and performance for most applications.

Compatibility Considerations

Always verify that your chosen sublimation spray works with your specific ink system and substrate. Some sprays are optimized for Sawgrass inks, others for Epson-based systems, and some claim universal compatibility. Reading reviews from users with similar setups helps avoid compatibility issues that manufacturers don’t always advertise clearly.

Temperature requirements also vary by product. Most sublimation sprays work with standard sublimation temperatures of 380-400°F, but some specialty formulations require adjustments. Check product specifications and run test prints before committing to large production runs.

Common Mistakes to Avoid When Using Sublimation Spray

Even experienced crafters make errors that compromise their sublimation spray results. Understanding these pitfalls helps you avoid wasted materials, customer complaints, and business losses. Let’s examine the most frequent mistakes and how to prevent them.

Over-Application and Dripping

The single biggest mistake is applying sublimation spray too heavily in an attempt to ensure complete coverage. Thick application causes several problems: drips that create uneven coating, longer drying times, stiff hand feel on fabrics, and wasted product. The coating can also transfer to your heat press platens, creating ghosting on subsequent prints.

Instead, remember this rule: multiple thin coats beat one thick coat every time. Set a timer between coats to ensure proper drying. Light application also preserves the natural texture and drape of fabrics, which customers appreciate on wearable items.

Insufficient Drying Time

Rushing the drying process ruins prints and damages equipment. Wet sublimation spray will steam during heat pressing, causing blurry images, color bleeding, and potential press damage. It may also stick to your transfer paper, tearing the design as you remove it. Even if the surface feels dry to touch, the coating needs time for complete solvent evaporation and polymer cross-linking.

Professional print shops use commercial heat lamps or convection dryers to speed curing while ensuring thoroughness. Home crafters can use hair dryers on cool settings or simply plan their workflow to allow overnight drying between coating and printing.

Ignoring Environmental Conditions

Temperature and humidity dramatically affect sublimation spray performance. Cold conditions cause the spray to go on thick and uneven. High humidity prevents proper drying and can cause moisture to become trapped under the coating. Many failed prints blamed on bad spray are actually environmental issues that proper workspace control would have prevented.

Monitor your workspace with a temperature/humidity meter (available for under $20). If conditions aren’t ideal, adjust your technique with additional drying time or thinner coats. Some printers wait for ideal weather conditions for large production runs rather than fighting environmental challenges.

Business Applications and Profit Potential

Sublimation spray opens profitable business opportunities that justify the investment in materials and learning curve. Understanding market demand and pricing strategies helps you maximize returns while building a sustainable customer base.

Custom Apparel Without Minimums

Traditional screen printing requires minimum orders to justify setup costs. With sublimation spray, you can profitably produce single custom cotton shirts, making you competitive in the print-on-demand market. This capability is perfect for small businesses, event merchandise, family reunion shirts, and personalized gifts where customers want one-off designs.

Pricing analysis shows successful shops charging $25-45 for custom cotton t-shirts with sublimation spray printing. Material costs (blank shirt, spray, ink, transfer paper) typically run $5-8 per item, leaving healthy profit margins even accounting for labor and overhead. Volume pricing encourages larger orders while maintaining per-unit profitability.

Home Décor and Gift Items

The personalized home décor market continues growing as consumers seek unique items that reflect their personality. Sublimation spray enables you to create custom wooden signs, canvas prints, decorative tiles, and fabric wall art that command premium prices. These items have higher perceived value than apparel, allowing markup percentages of 300-500%.

One successful case study involves a mother who started a side business creating custom family name signs on wood using sublimation spray. She sources 12×18 inch wood panels for $4 each, applies $1 worth of spray, and creates designs customers provide. Selling these signs for $45-65 each on Etsy and at local craft fairs, she generates $2,000-3,000 monthly profit working part-time.

Corporate and Event Merchandise

Businesses need promotional products that stand out and get used repeatedly. Custom bags, drinkware, notebooks, and apparel created with sublimation spray fit this need perfectly. The durability of sublimation printing ensures logos stay vibrant through years of use, providing ongoing brand exposure that cheap screen printing can’t match.

Target corporate clients by showcasing sample products at business networking events. Offer package deals for conferences, trade shows, and employee appreciation events. Many corporate buyers value the eco-friendly aspects of sublimation printing and will pay premium prices for sustainable merchandise options.

Troubleshooting Guide for Sublimation Spray Issues

Even with proper technique, you’ll occasionally encounter problems with sublimation spray applications. This troubleshooting guide addresses the most common issues and their solutions, helping you maintain consistent quality and minimize wasted materials.

Blotchy or Uneven Color Transfer

Uneven color usually indicates inconsistent sublimation spray application. The substrate has areas with too much coating (darker, more saturated) and areas with too little (lighter, washed out). This happens when spray technique varies across the surface or when you skip areas thinking they’re already covered.

Solutions include:

- Using consistent spray patterns with measured overlaps

- Rotating the substrate 90 degrees between coats for crosshatch coverage

- Applying spray in a well-lit area where you can see wet versus dry areas

- Using spray in a box or booth to see overspray patterns

- Keeping consistent distance from surface throughout application

If you discover uneven coating after drying, you can apply additional coats to light areas, but complete recoating usually produces better results than spot-fixing.

Design Not Transferring or Fading Quickly

When designs don’t transfer completely or fade after a few washes, the sublimation spray coating likely didn’t bond properly with the substrate. This can result from contamination on the surface before spraying, insufficient coating thickness, or incorrect heat press parameters for the coated material.

Check these factors: Was the surface properly cleaned and dried? Did you apply enough coats (typically 2-4 for most materials)? Did you allow full cure time before printing? Are you using correct temperature, pressure, and dwell time? Cotton and natural fibers often require slight adjustments from polyester settings even when treated with spray.

Stiff or Uncomfortable Hand Feel on Fabrics

Nobody wants to wear a t-shirt that feels like cardboard. Excessive sublimation spray application creates stiff, plasticky fabric that customers will reject. The spray contains polymers that add body to fabric, so finding the balance between adequate coating for good color transfer and maintaining fabric drape is essential.

Achieving soft hand feel requires light coats with thorough drying between applications. Some printers also wash coated garments after printing and heat setting to remove any surface residue, though this step isn’t always necessary with quality sprays properly applied. Test different coating techniques on scrap fabric to find your optimal balance.

Advanced Techniques for Professional Results

Once you’ve mastered basic sublimation spray application, these advanced techniques will elevate your work to professional levels that command premium prices and create repeat customers.

Gradient and Layered Coating Effects

Creative coating techniques produce unique artistic effects impossible with standard sublimation. Try applying sublimation spray in gradient patterns, heavier in some areas and lighter in others. When you press your design, color intensity varies across the image, creating depth and visual interest. This technique works beautifully on wood signs where you want the grain to show through in certain areas.

Layered coating with stencils creates defined areas of full-color printing surrounded by bare or lightly coated substrate. Fashion designers use this technique to create shirts with strategic placement prints against natural cotton background. The contrast between printed and unprinted areas adds sophistication that appeals to design-conscious customers.

Combining with Other Decoration Methods

Sublimation spray doesn’t have to work alone. Progressive printers combine it with vinyl, embroidery, screen printing, and direct-to-garment methods for hybrid designs that maximize each technique’s strengths. For example, sublimate a detailed photo onto sprayed cotton, then add raised vinyl text or embroidered accents. These multi-method designs justify higher prices and differentiate your work from competitors.

The key is understanding which decoration method goes first. Generally, apply sublimation spray and press your sublimation design first, then add other elements. Heat from subsequent pressing steps can actually improve sublimation bonding while applying vinyl or heat-transfer materials.

Color Management and Profiling

Serious professionals create custom color profiles for sublimation spray combinations with specific substrates. Colors don’t transfer identically on coated cotton versus coated wood versus polyester. Building ICC profiles for your most-used material combinations ensures consistent, predictable color matching that satisfies picky customers.

While this process requires colorimeter hardware and profiling software, the investment pays off for businesses doing significant volume. You’ll reduce reprints, improve customer satisfaction, and gain competitive advantage through superior color accuracy.

Health, Safety, and Environmental Considerations

Using sublimation spray safely protects your health and the environment while maintaining legal compliance for business operations. These considerations become increasingly important as you scale production.

Proper Ventilation Requirements

Most sublimation spray products contain chemicals that shouldn’t be heavily inhaled, even water-based formulations. Apply spray in well-ventilated areas with good air circulation. Outdoor application works great in suitable weather. Indoor application requires exhaust fans or spray booths that capture overspray and fumes, protecting both you and your workspace from contamination.

Professional print shops install dedicated spray booths with filtered exhaust systems. These enclosed chambers contain overspray while pulling fumes away from the operator. For home businesses, a simple box fan positioned to blow spray mist away from your breathing zone provides basic protection. Upgrade to better ventilation systems as your business grows.

Personal Protective Equipment

Always wear appropriate PPE when applying sublimation spray. At minimum, use nitrile gloves to prevent skin contact and a particulate respirator mask rated for organic vapors (N95 or better). Safety glasses protect your eyes from overspray. Long sleeves and aprons prevent spray from settling on your clothing and skin.

These precautions aren’t just about immediate safety. Repeated exposure to coating chemicals can cause sensitization, where you develop allergic reactions or respiratory problems over time. Professional applicators also use ventilated spray hoods for additional protection during high-volume production.

Environmental Responsibility

Dispose of empty sublimation spray cans according to local hazardous waste guidelines. Never pour unused spray down drains or into regular trash. Most spray products are flammable and require special disposal. Contact your local waste management authority for proper disposal options, which often include hazardous household waste collection events.

Consider the environmental impact of your entire workflow. Choose water-based sublimation spray formulations when possible, as they have lower VOC emissions. Recycle transfer paper when feasible. Use energy-efficient heat presses. These choices appeal to eco-conscious customers and reduce your business’s environmental footprint.

Comparing Sublimation Spray to Alternative Methods

Understanding how sublimation spray stacks up against other decoration methods helps you choose the right technique for each project and explain value to customers.

Sublimation Spray vs. Screen Printing

Screen printing remains the industry standard for large cotton apparel orders, but sublimation spray offers distinct advantages for small runs and complex designs. Screen printing requires separate screens for each color, making setup expensive and time-consuming for orders under 50 pieces. Sublimation with spray handles full-color designs with zero setup cost, making it profitable for single-item orders.

However, screen printing costs less per unit on large runs and produces more opaque colors on dark garments. Sublimation spray works best on white or light-colored materials since sublimation dye is translucent. Understanding these tradeoffs helps you recommend the right method for each customer’s needs and budget.

Sublimation Spray vs. Direct-to-Garment Printing

DTG printing also handles full-color designs on cotton without setup costs, making it direct competition for sublimation spray in some markets. DTG produces slightly softer hand feel and works on darker garments with white underbase printing. However, DTG printers cost $15,000-40,000 versus the minimal investment needed for sublimation spray systems.

Durability comparison favors sublimation spray. The polymer coating bonds ink at molecular level, resisting fading through 50+ wash cycles. DTG prints begin fading noticeably after 20-30 washes depending on garment care. For customers prioritizing longevity, sublimation spray justifies premium pricing despite DTG’s popularity.

Sublimation Spray vs. Heat Transfer Vinyl

HTV creates bold, opaque designs on any fabric color but can’t reproduce photographs or complex gradients well. Sublimation spray excels at photo-realistic images and detailed designs but requires light-colored substrates. Many successful shops offer both methods, using each where it performs best.

From a business perspective, HTV requires material inventory in various colors and types. Sublimation spray needs only white or light blanks and spray stock. The simplified inventory can be advantageous for small businesses with limited storage. Production speed is comparable once you master either technique.

Essential Equipment and Supplies

Building an efficient sublimation spray printing setup requires more than just spray and a heat press. This section covers essential equipment and supplies that improve results and streamline workflow.

Heat Press Considerations

While any heat press works for sublimation, certain features make sublimation spray printing easier and more consistent. Digital temperature and pressure controls ensure repeatability between prints. Swing-away presses prevent substrate shifting when opening the machine. Large format presses (15×15 inches or bigger) accommodate most project sizes without requiring multiple pressing positions.

Auto-open presses with countdown timers prevent overcooking prints while allowing you to prepare the next item during pressing. This efficiency matters when scaling production. Budget $300-800 for a quality clamshell press or $600-2000 for a swing-away model. The investment pays for itself quickly through improved quality and productivity.

Spray Application Equipment

Many crafters start with aerosol can sublimation spray because it’s convenient and requires no additional equipment. However, refillable spray bottles and HVLP spray guns become more economical for regular production. These systems use concentrated spray formula that you dilute according to manufacturer specifications, reducing per-project cost by 40-60%.

Professional shops invest in HVLP (high volume, low pressure) spray guns that produce fine, even mist with minimal overspray. These guns connect to air compressors and allow precise control over spray pattern, volume, and droplet size. Setup costs $150-500 but pays back quickly for businesses coating multiple items daily.

Supporting Tools and Accessories

Quality matters in supporting supplies:

- Heat-resistant tape: Secures transfers without leaving residue

- Teflon sheets: Protects press platens from spray residue

- Lint rollers: Removes fiber debris before coating

- Spray booth or box: Contains overspray for clean application

- Temperature strips: Verifies actual press temperature

- Pressure test pads: Ensures even pressure distribution

- Moisture meter: Checks substrate dryness before coating

These accessories cost $50-150 total but dramatically improve consistency and reduce waste. Professional presentation with consistent quality separates successful businesses from hobbyists, and proper equipment makes that consistency achievable.

Creating a Production Workflow

Efficient sublimation spray production requires organized workflow that minimizes handling, reduces errors, and maximizes throughput. Developing standardized processes allows you to scale production without quality loss.

Batch Processing Strategy

Group similar items together for efficient production. Coat all cotton t-shirts on the same day, then all wood signs the next day. This batching reduces setup time, minimizes equipment changes, and allows you to maintain consistent technique for each material type. Apply sublimation spray to multiple items in one session, then let them cure while you work on other business tasks.

Create a physical production line in your workspace. Station 1 handles substrate preparation and cleaning. Station 2 is your spray area. Station 3 stores items during drying. Station 4 contains your heat press and finishing area. This organization prevents cross-contamination and helps you track order status easily.

Quality Control Checkpoints

Implement quality checks at every stage to catch problems before they affect customers. Inspect substrates for defects before coating. Check sublimation spray application for complete coverage before drying. Test press with scrap material before committing to final items. Examine finished products for color accuracy, coverage, and adhesion before packaging.

Document your quality standards with photos showing acceptable versus defective results. Train employees or contractors using these standards so everyone maintains consistency. A single quality-control rejection is cheaper than a customer complaint and negative review that damages your reputation.

Time and Cost Tracking

Know your true costs for sublimation spray projects to price profitably. Track time spent on each production stage: preparation, coating, drying, pressing, finishing. Calculate material costs including substrate, spray, ink, transfer paper, and packaging. Factor in overhead like rent, utilities, and equipment depreciation.

Successful print businesses know that a custom cotton t-shirt requiring $8 in materials and 15 minutes of labor actually costs $15-20 when you account for overhead and waste. Pricing at $35-45 retail provides healthy margin for growth while remaining competitive. Understanding your numbers prevents the mistake of staying busy while losing money.

Marketing Your Sublimation Spray Services

Building a profitable sublimation spray business requires more than technical skill. Effective marketing attracts customers, communicates value, and justifies premium pricing for superior quality products.

Showcasing Quality and Versatility

Create a portfolio demonstrating the range of items possible with sublimation spray. Include apparel, home décor, promotional products, gifts, and specialty items. High-quality photos showing detail and color accuracy help customers visualize their custom ideas. Before-and-after comparisons showing cotton shirts versus traditional polyester prints demonstrate your unique capabilities.

Video content performs exceptionally well for marketing printing services. Create short clips showing your process: applying sublimation spray, pressing designs, revealing finished products. Behind-the-scenes content builds trust and differentiates you from competitors who use stock photos. Post these videos on Instagram, TikTok, Facebook, and YouTube to reach different audience segments.

Educational Content Marketing

Position yourself as an expert by creating content that educates potential customers. Blog posts explaining sublimation printing benefits, video tutorials showing care instructions, infographics comparing decoration methods—all build authority and trust. Mention sublimation spray naturally while focusing on solving customer problems and answering their questions.

This educational approach attracts customers through organic search and social media sharing. When someone searches “how to customize cotton shirts” or “best method for photo gifts,” your content appears as a helpful resource. These informed prospects convert at higher rates and spend more because they understand the value you provide.

Strategic Partnership Development

Partner with complementary businesses that serve similar customers but don’t compete directly. Interior designers need custom pillows and wall art. Event planners need promotional items and signage. Wedding coordinators need personalized gifts and décor. Corporate HR departments need employee recognition awards and branded merchandise. Each represents a steady source of sublimation spray projects.

Develop wholesale pricing for partners who refer consistent volume. Provide sample products they can show clients. Create co-branded marketing materials that make them look good while promoting your services. These B2B relationships often prove more profitable and stable than consumer-direct marketing.

Industry Trends and Future Developments

The sublimation spray market continues evolving with new formulations, applications, and technologies. Staying current with these developments helps you maintain competitive advantage and identify new opportunities.

Eco-Friendly Formula Improvements

Consumer demand for sustainable products is driving development of more environmentally friendly sublimation spray formulations. Manufacturers are reducing VOC emissions, eliminating toxic compounds, and creating biodegradable options. Some new products use plant-based polymers rather than petroleum derivatives while maintaining performance comparable to traditional formulations.

This trend creates marketing opportunities for eco-conscious businesses. Highlighting your use of sustainable sublimation spray products appeals to consumers willing to pay premium prices for environmentally responsible goods. Expect continued innovation in this direction as environmental regulations tighten and consumer preferences shift.

Expanded Material Compatibility

Research continues into sublimation spray formulations that work with increasingly diverse materials. Recent developments include sprays specifically designed for denim, canvas shoes, ceramic tiles, and even some synthetic fabrics previously incompatible with sublimation. Each new material type opens additional product categories and market segments.

Smart crafters and business owners watch for these innovations and test new products early. Being first to market with novel product offerings establishes you as an innovator and captures market share before competition increases. Subscribe to industry publications and follow coating manufacturers on social media to stay informed.

Integration with Automation

As sublimation spray production scales up, automation technologies are entering the market. Automated spray systems apply consistent coating to large batches of substrates with minimal labor. Computer-controlled heat presses with automatic pressure adjustment optimize pressing for different substrate types. These technologies will initially be expensive but will eventually become accessible to small businesses.

Forward-thinking business owners should plan for this evolution. Understanding emerging technologies helps you make smart equipment investments and position your business for growth. The goal is maintaining quality while increasing capacity, and automation tools designed specifically for sublimation spray workflows will make this increasingly achievable.

Storage and Shelf Life Management

Proper storage of sublimation spray products and coated substrates ensures consistent results and prevents waste from spoilage. These seemingly minor details significantly impact profitability for production businesses.

Storing Unopened Sublimation Spray

Unopened sublimation spray cans and bottles typically have shelf life of 12-24 months when stored properly. Keep them in temperature-controlled environments between 60-80°F away from direct sunlight and heat sources. Extreme temperatures cause pressure changes in aerosol cans and can alter chemical composition of liquid formulations.

Store spray products upright on stable shelving away from your heat press and other equipment generating heat. Organize by purchase date using first-in-first-out inventory rotation. This prevents old product from sitting unused past expiration while you use fresher stock. Check expiration dates quarterly and prioritize using products approaching their limit.

Managing Coated Substrate Inventory

Pre-coating substrates speeds production for rush orders and high-volume projects. However, coated materials have limited shelf life before the polymer coating begins degrading. Most sublimation spray coatings remain effective for 30-90 days depending on storage conditions and formulation type.

Store coated items in sealed plastic bags or containers to prevent dust contamination and moisture exposure. Label each batch with coating date and spray type used. Keep coated inventory in cool, dry conditions away from humidity and temperature fluctuations. Rotate stock carefully, using older coated items before fresher ones to minimize waste.

FAQs About Sublimation Spray

What exactly is sublimation spray used for?

Sublimation spray is used to create a polymer coating on non-polyester materials that allows them to accept sublimation ink during heat pressing. It enables you to sublimate designs onto cotton, wood, leather, canvas, and other natural materials that normally wouldn’t work with sublimation printing. The spray essentially creates an artificial polyester-like surface that bonds with sublimation dye.

Can you wash items printed with sublimation spray?

Yes, items printed using sublimation spray are washable and durable when properly processed. Fabric items should be washed inside-out in cold water on gentle cycle and line dried or tumble dried on low heat. Properly coated and pressed sublimation prints typically last 50+ wash cycles before showing noticeable fading. Avoid chlorine bleach and fabric softeners which can break down the polymer coating.

How many coats of sublimation spray do I need?

Most materials require 2-4 light coats of sublimation spray for optimal results. Cotton fabrics typically need 2-3 coats, while porous materials like canvas may need 3-4 coats. Wood and hard surfaces usually require 2-3 coats. The key is applying multiple thin coats rather than one thick coat, allowing proper drying time between applications for best adhesion and color transfer.

Is sublimation spray toxic or dangerous?

Most sublimation spray products contain chemical compounds that require proper handling but aren’t highly toxic. Water-based formulations have low toxicity and minimal VOC emissions. Always use spray in well-ventilated areas, wear appropriate protective equipment including gloves and respirator mask, and follow manufacturer safety guidelines. Proper ventilation and PPE make sublimation spray safe for regular use.

Can you use sublimation spray on dark fabrics?

Sublimation spray works best on white or light-colored materials because sublimation ink is translucent rather than opaque. On dark fabrics, colors will appear muted or may not show at all. Some manufacturers offer white base coat sprays that you apply before sublimation spray to create a light surface on darker materials, though results vary. For consistently good results on dark fabrics, other printing methods like DTG or screen printing work better.

How long does sublimation spray take to dry?

Drying time for sublimation spray varies by formulation, coating thickness, and environmental conditions. Water-based sprays typically dry to touch in 10-30 minutes but require 4-24 hours for complete cure before heat pressing. Solvent-based formulations may dry faster, in 5-15 minutes per coat. However, always allow full cure time recommended by manufacturer before printing to ensure proper bonding and avoid press contamination.

Does sublimation spray work with all sublimation printers?

Sublimation spray is generally compatible with all sublimation printing systems including Sawgrass, Epson-converted printers, and other brands. The spray creates a compatible surface for the sublimation dye regardless of printer type. However, some spray formulations are optimized for specific ink systems. Check manufacturer compatibility information and run test prints when trying new spray products with your equipment.

Where can I buy sublimation spray?

You can purchase sublimation spray from specialized printing suppliers, craft stores like Michael’s or Hobby Lobby, online retailers including Amazon and Etsy, and directly from manufacturers like SubliGlaze or A-Sub. Prices range from $15-35 per bottle or can, with bulk purchasing options available for production businesses. Compare coverage rates and reviews when selecting products rather than just comparing prices.

Can sublimation spray be used in a tanning spray booth?

While both use spray application methods, sublimation spray and tanning spray serve completely different purposes with different equipment requirements. A tanning spray booth is designed for airbrush tanning applications with specific ventilation for cosmetic products. You could theoretically use a tanning booth’s ventilation system for applying sublimation spray, but cross-contamination concerns make this inadvisable. It’s better to use dedicated equipment for each application.

How much does sublimation spray cost per project?

The cost of sublimation spray per project depends on item size and how many coats you apply. A standard t-shirt typically requires $0.50-1.50 worth of spray. Larger items like tote bags might use $1-2 worth. Small items like coasters use $0.25-0.50 worth. When you factor in the substrate cost, transfer paper, and ink, a basic cotton t-shirt project costs approximately $5-8 in materials, allowing healthy profit margins when selling at $25-45 retail.

Ready to transform your sublimation printing capabilities? Investing in quality sublimation spray opens up countless new product possibilities that can significantly grow your creative business or print shop. Start with small test batches on various materials to master the technique, then scale up as you discover which products resonate with your target market. The learning curve is manageable, and the profit potential makes sublimation spray one of the most valuable additions to any sublimation printing operation.

Whether you’re a hobbyist crafter looking to expand your product line or a professional print shop seeking to serve the cotton apparel market, sublimation spray provides the versatility and quality results that customers demand. The initial investment is minimal compared to other printing methods, and the skills you develop will serve your business for years to come.