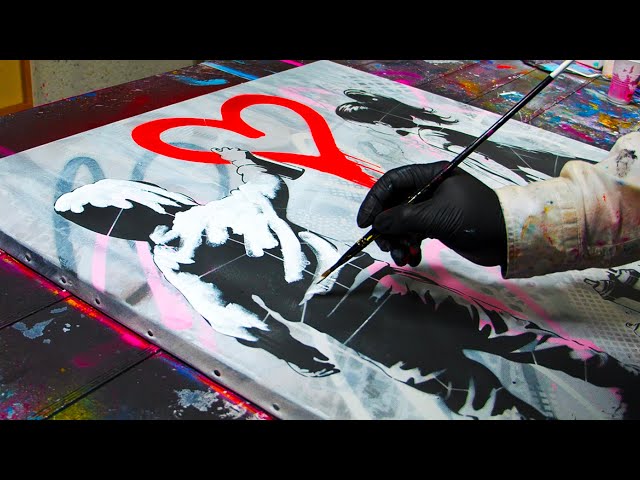

Creating stunning artwork and decorative projects has never been more accessible thanks to the versatile combination of stencil and spray paint techniques. Whether you’re a professional artist, DIY enthusiast, or business owner looking to enhance your branding materials, mastering these methods can elevate your creative output significantly. The art of stenciling with spray paint offers unlimited possibilities for transforming ordinary surfaces into extraordinary masterpieces, from custom signage and home décor to industrial applications and street art.

The popularity of stencil and spray paint projects has surged in recent years, driven by social media platforms showcasing incredible transformations and the growing maker movement. Professional artists report that combining traditional stenciling techniques with modern spray paint formulations can produce results that rival expensive custom printing methods, often at a fraction of the cost. This comprehensive approach to creative expression allows both beginners and experienced craftspeople to achieve professional-quality results with relatively simple tools and techniques.

Understanding Stencil and Spray Paint Fundamentals

Stencil and spray paint work together through a subtractive process where the stencil acts as a mask, allowing paint to reach only specific areas of your surface. This fundamental principle enables precise control over design placement and color application, making it possible to create intricate patterns, text, and imagery with remarkable consistency. The key to success lies in understanding how different stencil materials interact with various spray paint formulations and surface types.

Professional stencil artists emphasize that the relationship between stencil material and spray paint viscosity directly impacts the final result quality. Thicker paints may require more aggressive application techniques, while thinner formulations can seep under stencil edges if not properly managed. Understanding these interactions allows creators to select optimal material combinations for their specific project requirements, ensuring consistent results across multiple applications.

Essential Materials for Stencil and Spray Paint Projects

The foundation of any successful stencil and spray paint project begins with selecting appropriate materials. Quality stencils can be crafted from various materials, each offering distinct advantages depending on your project scope and durability requirements.

Stencil Material Options:

- Mylar plastic sheets – Durable, reusable, excellent for detailed designs

- Cardboard – Cost-effective, suitable for single-use applications

- Metal sheets – Industrial-grade durability for heavy commercial use

- Vinyl adhesive – Precise edge definition, ideal for curved surfaces

- Freezer paper – Temporary applications, easy removal without residue

Spray Paint Categories:

- Acrylic-based formulations – Fast-drying, low odor, versatile color options

- Enamel paints – Superior durability, glossy finish, weather-resistant

- Specialty coatings – Metallic, textured, glow-in-the-dark varieties

- Primer sprays – Surface preparation for optimal paint adhesion

- Protective topcoats – UV resistance, scratch protection, longevity enhancement

Professional contractors often invest in terpene spray solutions for surface preparation, as these natural solvents can improve paint adhesion on challenging surfaces while maintaining environmental safety standards.

Professional Stencil Creation Techniques

Creating effective stencils requires careful consideration of design elements, structural integrity, and intended use applications. Professional stencil and spray paint artists develop systematic approaches to stencil creation that ensure consistent results across multiple projects while minimizing material waste and production time.

The design phase represents the most critical aspect of stencil creation, as errors made during initial planning multiply throughout the production process. Successful designs must account for paint flow dynamics, stencil material limitations, and the specific characteristics of target surfaces. Professional designers recommend creating test versions using inexpensive materials before committing to final production runs, particularly for complex or large-scale projects.

Digital Design and Cutting Methods

Modern stencil and spray paint workflows increasingly incorporate digital design tools and precision cutting equipment to achieve professional-quality results. Computer-aided design software enables artists to create precise templates, test different configurations virtually, and optimize cutting paths for material efficiency.

Digital Design Advantages:

- Precise measurement control and scaling capabilities

- Easy modification and version management

- Optimal material utilization through nesting algorithms

- Consistent reproduction across multiple stencils

- Integration with automated cutting systems

Cutting Equipment Options:

- Craft knives – Manual precision for small-scale projects

- Vinyl plotters – Automated cutting for adhesive materials

- Laser cutters – High-precision cutting for complex designs

- CNC routers – Industrial-scale production capabilities

- Hot knife tools – Clean cuts in synthetic materials

Professional stencil manufacturers report that laser-cut stencils produce superior edge quality compared to manual cutting methods, resulting in sharper paint lines and reduced bleeding under stencil edges. This enhanced precision becomes particularly important for detailed text and intricate pattern reproduction.

Advanced Spray Paint Application Techniques

Mastering stencil and spray paint application requires understanding proper spray patterns, distance control, and layering techniques. Professional results depend heavily on consistent application methods that account for environmental conditions, surface preparation, and paint characteristics.

The spray technique itself involves much more than simply pointing and spraying. Successful artists develop muscle memory for optimal can distance, movement speed, and overlap patterns that ensure even coverage without overspray or color buildup. Environmental factors such as humidity, temperature, and air movement can significantly impact paint behavior, requiring technique adjustments for optimal results.

Spray Pattern Control and Coverage

Professional stencil and spray paint application follows systematic patterns that ensure complete coverage while minimizing waste and achieving consistent color density. The key lies in maintaining steady movement speeds and consistent distances throughout the entire application process.

Optimal Spray Techniques:

- Distance control – Maintain 6-8 inches from surface for most applications

- Movement patterns – Use overlapping passes in consistent directions

- Speed consistency – Steady motion prevents buildup and drips

- Edge treatment – Special attention to stencil boundaries prevents bleeding

- Multiple light coats – Build color gradually for even saturation

Environmental Considerations:

- Temperature range – Optimal application between 65-75°F

- Humidity levels – Lower humidity improves paint flow and drying

- Air circulation – Gentle airflow aids drying without disturbing wet paint

- Surface temperature – Avoid extremely hot or cold surfaces

- Dust protection – Shield work area from airborne contaminants

Case studies from automotive customization shops demonstrate that proper spray technique can reduce paint consumption by up to 30% while improving finish quality significantly. These efficiency gains become particularly important for large-scale commercial applications where material costs represent substantial project expenses.

Surface Preparation and Primer Applications

The success of any stencil and spray paint project depends heavily on proper surface preparation and primer selection. Different surface materials require specific preparation techniques to ensure optimal paint adhesion and longevity. Professional applicators invest significant time in surface preparation because inadequate preparation represents the primary cause of paint failure in stencil applications.

Surface contamination, including oils, dirt, and previous coatings, can prevent proper paint adhesion regardless of application technique quality. Professional preparation protocols address these contamination sources systematically, creating optimal conditions for paint bonding. The investment in proper preparation typically pays dividends through improved finish durability and reduced maintenance requirements.

Material-Specific Preparation Methods

Each surface material presents unique challenges that require tailored preparation approaches. Understanding these material characteristics enables stencil and spray paint artists to select appropriate preparation methods and achieve professional results consistently.

Metal Surface Preparation:

- Degreasing – Remove oils and manufacturing residues

- Abrasion – Light sanding improves mechanical adhesion

- Rust treatment – Address corrosion before paint application

- Primer selection – Metal-specific primers prevent corrosion

- Flash rust prevention – Quick primer application after cleaning

Wood Surface Preparation:

- Sanding progression – Gradual grit reduction for smooth finish

- Grain filling – Address open grain woods for uniform appearance

- Moisture content – Ensure proper drying before paint application

- Knot sealing – Prevent resin bleeding through paint film

- Dust removal – Thorough cleaning between preparation steps

Plastic Surface Preparation:

- Static elimination – Remove electrostatic dust attraction

- Adhesion promotion – Specialized primers for plastic bonding

- Flexibility considerations – Accommodate thermal expansion

- Chemical compatibility – Avoid solvent damage to substrate

- Surface energy modification – Improve wetting characteristics

Color Theory and Design Psychology in Stencil Work

Professional stencil and spray paint applications require understanding color relationships and psychological impacts to create effective visual communications. Color selection influences viewer perception, emotional response, and message retention in ways that extend far beyond aesthetic preferences. Strategic color choices can enhance brand recognition, improve safety communications, and create desired atmospheric effects in architectural applications.

The psychology of color perception varies across cultural contexts and individual experiences, but certain color relationships demonstrate consistent effects across diverse populations. Understanding these universal principles enables designers to make informed color selections that support project objectives while appealing to target audiences effectively.

Color Combination Strategies

Effective stencil and spray paint color schemes follow established design principles that create visual harmony while maintaining adequate contrast for readability and impact. Professional designers develop color palettes that consider viewing distance, lighting conditions, and surrounding environmental colors.

Primary Color Relationships:

- Complementary schemes – Opposite colors create maximum contrast

- Analogous combinations – Adjacent colors provide harmonious blends

- Triadic arrangements – Three evenly-spaced colors offer vibrant variety

- Monochromatic variations – Single color in multiple shades and tints

- Split-complementary – Base color plus two adjacent to its complement

Practical Application Considerations:

- Contrast ratios – Ensure readability across different viewing conditions

- Color temperature – Warm vs. cool color psychological effects

- Saturation levels – High saturation for attention, low for subtlety

- Value relationships – Light/dark contrast for dimensional effects

- Cultural associations – Consider color meanings in target demographics

Research from environmental psychology studies indicates that color choices in public spaces can influence behavior patterns, stress levels, and productivity measures. These findings have significant implications for commercial stencil and spray paint applications in workplace environments, retail spaces, and educational facilities.

Industrial and Commercial Applications

The versatility of stencil and spray paint techniques extends far beyond artistic expression into practical commercial and industrial applications. Businesses across various industries rely on these methods for cost-effective marking, branding, and safety communication solutions. The scalability and repeatability of stencil-based marking systems make them particularly valuable for manufacturing, logistics, and facility management operations.

Industrial applications often require specialized paint formulations that withstand harsh environmental conditions, chemical exposure, and mechanical wear. Understanding these performance requirements enables specification of appropriate materials and application techniques that deliver long-term value in demanding commercial environments.

Manufacturing and Logistics Applications

Stencil and spray paint systems provide efficient solutions for product marking, inventory management, and process identification in manufacturing environments. These applications often require rapid application capabilities, consistent reproduction, and durability under industrial conditions.

Manufacturing Applications:

- Part identification – Serial numbers, batch codes, and specifications

- Quality control marking – Inspection status and approval indicators

- Assembly guidance – Process step identification and routing

- Safety warnings – Hazard identification and handling instructions

- Inventory tracking – Location coding and rotation management

Logistics and Warehousing:

- Floor marking – Traffic patterns, storage zones, and safety areas

- Container identification – Shipping codes and destination marking

- Equipment labeling – Maintenance schedules and operating parameters

- Hazard communication – Chemical compatibility and storage requirements

- Inventory organization – Product categories and location systems

Case studies from automotive manufacturing facilities demonstrate that stencil and spray paint marking systems can reduce labeling costs by up to 60% compared to adhesive label systems while providing superior durability in harsh production environments. These cost savings become particularly significant in high-volume production scenarios where traditional labeling methods represent substantial ongoing expenses.

Troubleshooting Common Stencil and Spray Paint Issues

Even experienced practitioners encounter challenges when working with stencil and spray paint applications. Understanding common problems and their solutions enables quick resolution of issues that could otherwise compromise project quality or timeline. Professional troubleshooting approaches focus on identifying root causes rather than addressing symptoms, leading to more effective long-term solutions.

The most frequent issues in stencil work relate to paint bleeding under stencil edges, uneven coverage, and premature stencil failure. Each of these problems typically stems from specific cause categories that can be systematically addressed through proper technique modifications or material selection changes.

Paint Bleeding and Edge Definition Problems

Paint bleeding represents one of the most frustrating issues in stencil and spray paint work, often requiring complete project restart when severe. Understanding the mechanisms that cause bleeding enables preventive measures that maintain crisp edge definition consistently.

Common Bleeding Causes:

- Excessive spray pressure – High pressure forces paint under stencil edges

- Inadequate stencil adhesion – Poor surface contact allows paint infiltration

- Overapplication – Thick paint layers create hydrostatic pressure

- Incompatible materials – Paint solvents attack stencil materials

- Environmental conditions – High humidity affects paint viscosity

Prevention Strategies:

- Proper stencil sealing – Ensure complete edge contact with surface

- Controlled application – Multiple light coats instead of heavy coverage

- Appropriate spray distance – Maintain optimal working distance consistently

- Material compatibility – Test paint/stencil combinations before use

- Environmental control – Manage temperature and humidity conditions

Correction Techniques:

- Immediate removal – Clean bleeding while paint remains wet

- Masking corrections – Cover mistakes with additional stencil elements

- Touch-up applications – Blend corrections with surrounding areas

- Surface refinishing – Complete restart for severe bleeding issues

- Design modifications – Adjust patterns to accommodate corrections

Professional restoration shops report that implementing systematic bleeding prevention protocols reduces project rework by over 80%, significantly improving both profitability and customer satisfaction rates.

Maintenance and Longevity of Stencil Work

Proper maintenance protocols significantly extend the lifespan of stencil and spray paint applications, particularly in demanding outdoor or industrial environments. Understanding degradation mechanisms enables development of maintenance schedules that preserve appearance and functionality while minimizing long-term costs.

Environmental factors such as UV exposure, temperature cycling, and chemical contamination cause gradual deterioration of paint films and substrate materials. Proactive maintenance addresses these factors before they compromise project integrity, typically at much lower cost than complete refinishing operations.

Protective Coating Systems

Stencil and spray paint applications benefit significantly from appropriate protective coating systems that shield the base paint from environmental damage while maintaining visual clarity and color integrity. Professional-grade protective systems can extend service life by 300-500% in harsh environments.

Protective Coating Options:

- Clear acrylic topcoats – UV protection with minimal appearance change

- Polyurethane systems – Superior chemical and abrasion resistance

- Wax-based protectants – Renewable protection for temporary applications

- Nano-ceramic coatings – Advanced protection with self-cleaning properties

- Anti-graffiti films – Sacrificial layers for easy cleaning and replacement

Application Timing:

- Immediate protection – Apply within 24 hours of base paint curing

- Seasonal maintenance – Reapply protective coatings annually or bi-annually

- Damage assessment – Regular inspection for coating integrity

- Preventive replacement – Address coating failure before substrate damage

- Environmental monitoring – Adjust schedules based on exposure conditions

Equipment Selection and Maintenance

Professional stencil and spray paint results require appropriate equipment selection and regular maintenance protocols. Investment in quality tools typically pays dividends through improved results, increased efficiency, and reduced material waste. Understanding equipment capabilities and limitations enables optimal tool selection for specific project requirements.

Equipment maintenance represents a critical but often overlooked aspect of professional stencil work. Proper maintenance protocols extend equipment life, maintain performance consistency, and prevent costly project delays due to equipment failures.

Spray Equipment Categories

Different stencil and spray paint applications require specialized equipment configurations that optimize performance for specific use cases. Understanding these equipment categories enables informed selection decisions based on project scope and quality requirements.

Handheld Aerosol Systems:

- Standard spray cans – Convenient for small projects and touch-ups

- Professional aerosols – Higher-quality paints and improved spray patterns

- Refillable systems – Cost-effective for repeated use applications

- Specialty formulations – Textured, metallic, and effect coatings

- Precision control – Adjustable spray patterns and flow rates

Airbrush Systems:

- Single-action brushes – Simple operation for basic applications

- Double-action control – Independent air and paint flow adjustment

- Gravity-feed designs – Efficient paint utilization and easy cleaning

- Siphon-feed systems – Large paint capacity for extended use

- Professional maintenance – Regular cleaning and calibration requirements

HVLP Spray Systems:

- High transfer efficiency – Reduced overspray and material waste

- Professional finish quality – Consistent atomization and coverage

- Variable pressure control – Adjustment for different paint viscosities

- Large project capability – High production rates and paint capacity

- Investment considerations – Higher initial cost with long-term value

| Equipment Type | Initial Cost | Operating Cost | Quality Level | Project Scale |

|---|---|---|---|---|

| Aerosol Cans | Low ($5-15) | High | Good | Small |

| Refillable Aerosol | Medium ($50-150) | Medium | Good | Medium |

| Airbrush System | Medium ($100-500) | Low | Excellent | Detail Work |

| HVLP System | High ($300-2000) | Low | Excellent | Large Scale |

Business Applications and ROI Considerations

Stencil and spray paint techniques offer significant return on investment opportunities for businesses seeking cost-effective marking, branding, and decorative solutions. Understanding the economic benefits and implementation considerations enables informed decisions about incorporating these methods into business operations.

The scalability of stencil-based systems makes them particularly attractive for businesses with variable volume requirements or seasonal demand patterns. Unlike fixed printing systems that require minimum quantities for cost effectiveness, stencil and spray paint methods remain economical for single-unit applications while scaling efficiently for large production runs.

Cost-Benefit Analysis Framework

Professional evaluation of stencil and spray paint business applications requires comprehensive cost-benefit analysis that considers both direct costs and indirect benefits such as flexibility, speed, and customization capabilities.

Direct Cost Factors:

- Initial equipment investment – Tools, materials, and setup costs

- Material costs per application – Paint, stencils, and consumables

- Labor requirements – Setup time, application time, and cleanup

- Facility costs – Workspace, ventilation, and storage requirements

- Training and certification – Skill development and safety compliance

Indirect Benefit Factors:

- Customization flexibility – Ability to modify designs quickly

- Inventory reduction – On-demand production eliminates storage needs

- Speed advantages – Rapid turnaround compared to outsourced alternatives

- Quality control – Direct oversight of production quality

- Market responsiveness – Quick adaptation to changing requirements

Business case studies from sign manufacturing companies indicate that transitioning from outsourced to in-house stencil and spray paint capabilities typically achieves payback periods of 6-18 months, depending on volume levels and application complexity.

Ready to transform your creative projects with professional stencil and spray paint techniques? Start with high-quality materials and follow these proven methods to achieve stunning results that rival expensive custom alternatives. Whether you’re creating art, signage, or industrial markings, mastering these versatile techniques opens unlimited creative possibilities.

For professional-grade stencil and spray paint supplies and expert guidance, explore our comprehensive selection of materials and tools designed for both beginners and experienced professionals.

Frequently Asked Questions About Stencil and Spray Paint

What is the best paint type for stencil and spray paint projects? Acrylic-based spray paints offer the best balance of durability, color selection, and ease of use for most stencil and spray paint applications. They dry quickly, have low odor, and work well on various surfaces including wood, metal, and plastic.

How do I prevent paint bleeding under my stencil edges? Prevent bleeding by ensuring complete stencil adhesion to the surface, using light multiple coats instead of heavy application, maintaining proper spray distance (6-8 inches), and applying paint perpendicular to the surface rather than at angles.

What materials make the best reusable stencils for spray paint? Mylar plastic sheets provide the best combination of durability and precision for reusable stencil and spray paint applications. They resist solvent damage, maintain sharp edges through multiple uses, and can be easily cleaned between applications.

How long should I wait between coats when using stencil and spray paint? Wait 5-10 minutes between light coats for most acrylic spray paints, allowing the surface to become tacky but not fully cured. This timing prevents color buildup while ensuring proper adhesion between layers.

Can I use stencil and spray paint techniques on outdoor surfaces? Yes, stencil and spray paint works excellently outdoors when using appropriate paint formulations and protective topcoats. Choose paints specifically designed for exterior use and apply protective clear coats for enhanced UV and weather resistance.

What safety equipment do I need for stencil and spray paint work? Essential safety equipment includes a proper respirator mask, safety glasses, disposable gloves, and adequate ventilation. Work in well-ventilated areas and consider using low-VOC paint formulations to minimize health risks.

How do I clean and maintain my stencils for multiple uses? Clean stencils immediately after use with appropriate solvents (usually the same solvent base as your paint), dry thoroughly, and store flat to prevent warping. Mylar stencils can be washed with soap and water for water-based paints.

What’s the difference between stencil and spray paint versus traditional brush painting? Stencil and spray paint methods provide faster application, more uniform coverage, smoother finishes, and better consistency for repeated designs compared to brush painting. However, brush painting offers more control for detail work and color blending.

How do I choose the right stencil size for my spray paint project? Consider viewing distance, surface size, and design complexity when selecting stencil dimensions. Text should be readable from intended viewing distance, and stencil size should be proportional to the surface area for balanced visual impact.

Can I create custom stencils for specific spray paint applications? Absolutely! Custom stencils can be created using computer design software and cut with craft knives, vinyl plotters, or laser cutters. This allows perfect customization for branding, specific text, or unique artistic designs in your stencil and spray paint projects.